+86-13532971605

English

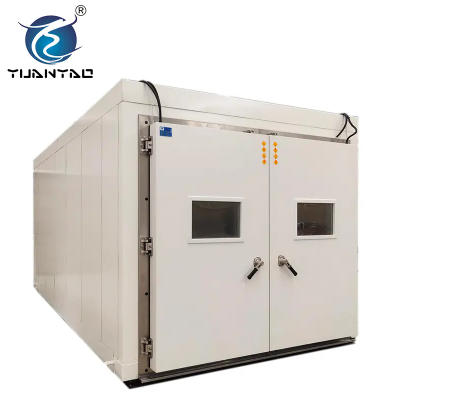

Walk-in temperature humidity chamber plays an important role in vehicle testing in the automotive industry. This equipment can simulate various extreme environmental conditions to ensure vehicle performance and safety in different temperature and humidity environments. However, venting gasoline is a necessary step during vehicle testing. This operation is not only related to the safety of the test but also to environmental protection and the accuracy of the test results. This article will discuss in detail from the following aspects why it is necessary to vent gasoline when conducting vehicle tests in a walk-in temperature humidity chamber.

Walk-in temperature humidity chamber can simulate extreme temperature and humidity environments, and the significant fluctuations in temperature during the test may cause rapid gasoline volatilization. Gasoline is a flammable liquid, and the gases it volatilizes can easily form explosive mixtures in a confined environment. If the concentration of combustible gases in the test chamber reaches a critical value, even a small spark or static electricity can trigger a fire or explosion, severely threatening the safety of test personnel and equipment. Therefore, to reduce risks, it is necessary to vent gasoline before conducting vehicle tests in a walk-in temperature humidity chamber effectively reduces potential explosion hazards and ensures the safety of the testing process.

From an environmental and health perspective, the harmful gases volatilized by gasoline pose potential threats to human health. A walk-in temperature humidity chamber is a sealed test environment; if gasoline is not vented, the volatilized gasoline gases may persist for a long time and be inhaled by test personnel, causing dizziness, nausea, and other symptoms, and potentially leading to more severe health issues. Furthermore, these volatile substances can also pollute the air quality inside the test chamber, affecting the accuracy of the test results. Venting gasoline is not only for protecting the health of test personnel but also for ensuring the reliability of test data and environmental sustainability.

During vehicle tests in a walk-in temperature humidity chamber, multiple repeated tests are usually required to verify the performance stability of the vehicle in various environments. If gasoline is not vented after each test, the residual gasoline may age or become contaminated, affecting the consistency of subsequent test results. Venting gasoline ensures that each test is conducted in the same initial state, which is crucial for improving the reliability and repeatability of the tests. Therefore, venting gasoline is not only a safety consideration but also essential for maintaining the scientific and rigorous nature of the tests.

In summary, venting gasoline is a crucial step in conducting vehicle tests in a walk-in temperature humidity chamber. This operation can eliminate potential safety hazards, protect the health of test personnel, and ensure the accuracy and consistency of test results. Whether from a safety, environmental, or scientific perspective, venting gasoline is an indispensable step in vehicle tests conducted in a walk-in temperature humidity chamber.