+86-13532971605

English

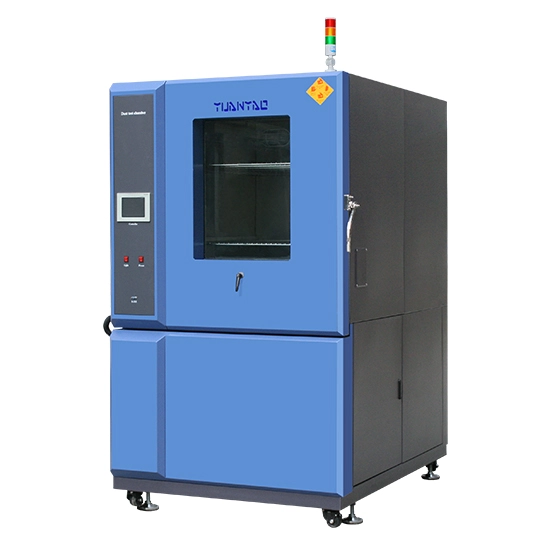

As we knew, a vacuum drying oven is widely used in medicine, food, light industry, chemical industry and other industries for low-temperature drying. The advantages of a vacuum oven are fast drying, low pollution, and no damage to the inherent quality of the dried items.

In order to improve the efficiency of users using the efficient vacuum oven, Yuanyao customer service staff will collect customer feedback questionnaires every year. Based on customer feedback, we have summarized several common faults and solutions for users as below.

1. There is no way to dry the sample when this type of industrial drying oven working

Reason: It may be caused by the wrong using vacuum drying ovens. The vacuum drying process needs to be performed in a closed environment. If the water vapor is generated during the drying process and is not discharged in time, which will cause the water vapor to enter the sample again.

Solution: Replenish some air into the inner chamber every once in a while, and then use the vacuum pump to extract the water vapor, so that the operation can prevent the phenomenon that there is no way to dry the sample.

2. When the industrial vacuum drying oven comes on vacuum suction phenomenon

Reason: wrong operation when turning off the vacuum pump, the correct way is to close the valve first and then turn off the vacuum pump. If the order is reversed, under the influence of vacuum negative pressure, the water or oil of the vacuum pump will be sucked back.

Solution: Follow the correct sequence of operations, first turn off the valve and then turn off the vacuum pump. If it is easy to make mistakes, a check valve should be added between the vacuum pump and the vacuum drying oven. When the vacuum pump stops, the check valve will close the valve instantly, and there will be no vacuum suction.

3. The air leakage phenomenon occurs after the vacuum drying oven is used for couple years

Reason: The biggest reason is probably not that the drying oven is broken, but that the seal is damaged and aging,

Solution: Just replace the sealing strip in time. If the problem still cannot be solved, it means the valve is damaged. Just replace some valves.

4. Quite a difference between the set temperature and the actual temperature in the vacuum drying oven.

Reason: Too often open and close the door or the temperature sensor is damaged

Solution: Try to reduce the number of opening and closing the door or replace the temperature sensor.

Yuanyao team contributes to supply a suitable solution to our customers, so we have various environment test equipments, including hot&cold tester, dust & water tester, salts spray & ozone aging test, pressure chamber...

Welcome to tell us your needs, we also supply customer service.