+86-13532971605

English

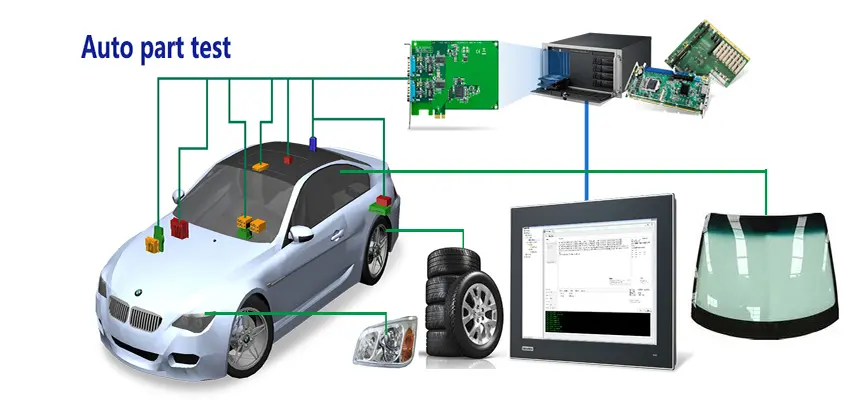

Automobiles are complex products composed of thousands of parts and have to pass various severe environmental conditions (transportation, storage, work, weather ... etc.), So the reliability of auto parts and their finished products is very important. Next, let us introduce what kind of test mainly be needed in this industry.

What is the relation between environment and automobile and auto parts?

| Environment | Influence on the product |

| High temperature | Aging, gasification, cracking, softening, melting, expansion and evaporation |

| Low temperature | Brittleness, icing, shrinkage and solidification, mechanical strength decrease |

| High relative humidity | Corrosion, electrolysis |

| Low relative humidity | Dehydration, brittlement, shrinkage, mechanical strength decrease |

| Low pressure | Mechanical default,sealing problem |

| Corrosive air | Corrosion, electrolysis, surface degradation, increased conductivity, increased contact resistance |

| Rapid temperature changes | Overheating causes crack deformation and mechanical failure |

| Accelerated vibration or impact | Component abrasion increases structural damage |

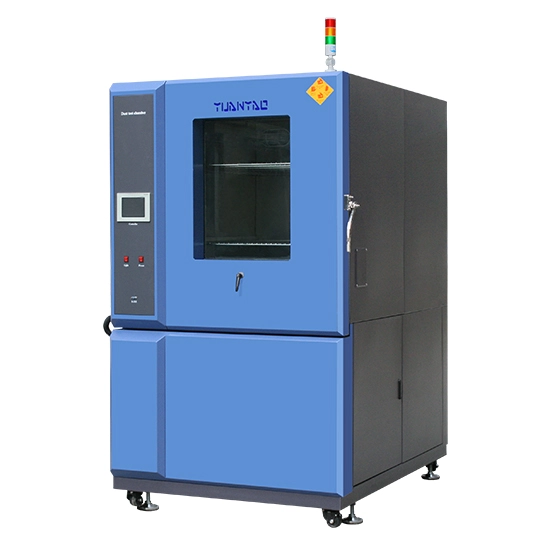

Therefore, we need to an environment testing equipment as below:

Temperature humidity cycle test, rapid rate temperature test, salt spray corrosion test, waterproof test, dustproof test, thermal shock test, etc.